With the exception of the Montesa Cota 4RT, Vertigo Combat and the Ossa TR280i, which are powered by an electronic injection system, all trial bikes are fueled by carburetion. Especially in two-stroke engines, which also make up the vast majority of the motorcycle fleet in this specialty, the importance of their condition and tuning is decisive in the performance of the motorcycle. Of course, it’s not the same to carburete the bike on a terrain at sea level than in the high mountains.

It is so important to have a good understanding of how the carburetor works and is maintained, that good old age and optimal performance can depend on it, or the opposite. We must not forget that Trial is a very particular specialty. Perhaps the only one in the engine where there are usually no displacement restrictions in competition.

Why? Simply because power isn’t the most important thing, especially for 90% of fans; What we’re really interested in is good torque and a good torque curve. Just take a look at the dimensions of the carburetors that equip motorcycles of other specialties, such as Motocross or Enduro.

The reason is that, while these have been designed with maximum performance in mind from an engine that works very revved, in Trial the engine usually works in the medium and low rev range – the maximum torque is reached around 3,000 rpm and the maximum power below 6,000 rpm. The explanation, therefore, is simple: when performing at low revs, the airflow to the cylinder is less and the small carburetor is more effective.

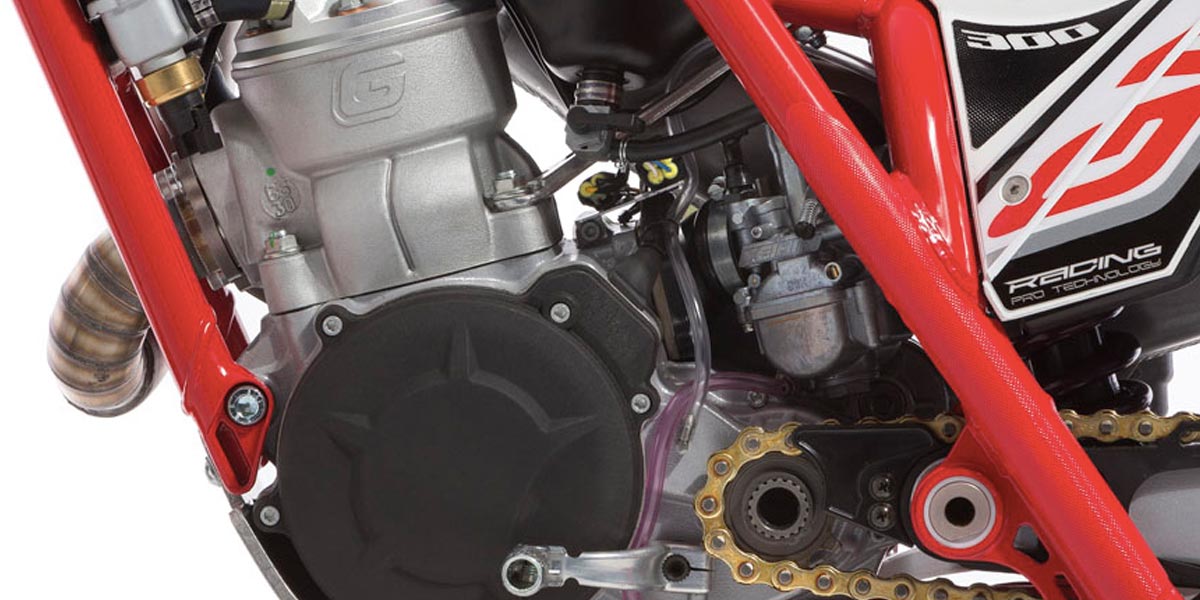

Externally you can see the air regulation screws (small) and idle regulation screws (large)

What does a rider demand from his Trial bike?

* Performance effectiveness from 1,000 rpm. As a curiosity, efficiently managing the behavior of the electronic injection in this low rev range has been the great brake for more 4-stroke models to be encouraged to replace their carburetors with injection.

* Progressive rev escalation, no bumps, maintaining good torque.

* A direct response, but at the same time smooth and easily modular.

* Good engine stretch and ability to withstand overrevs.

What elements does a carburetor have?

Basically, the standard bikes are equipped with one of these two carburetors: Dell ́Orto PHBL 26 mm – there is also a VHTS flat gate variant – or Keihin PWK – a more “pro” character. We must also remember that certain models – Beta or Scorpa prior to 2010 – have inverted controls and are adjusted from the right side of the bike.

In any case, the elements we are going to describe coincide for both models.

* Body: we refer to the aluminum frame where the rest of the components involved in carburetion are attached.

* Float: together with the valve, it is responsible for maintaining an optimal level of gasoline in the tank.

* Tank: This is the lower body or base of the carburetor.

* Rest: there is a hole for the fuel inlet (with a filter), a choke lever (cold start) and the top cover (it is crossed by the throttle cable).

You can see the floats, the low gum (centered), the choke gum (lower corner) and in the large central hole is the chimney (and the high gum is screwed on once the tank is placed)

* Bell: this is the cylindrical part where the accelerator grip acts, going up or down depending on the opening of the component. At the bottom we find a spring and a circular piece in charge of slowing down the needle.

* Needle: it is fixed to the bell by means of a small clip – this can vary its position to raise the bell more or less.

* Chimney: the needle slides into it. It acts as an emulsifier and is a long screw that is hidden in the center of the carburetor – accessed from the bottom.

* Chewing gum: this is probably one of the most well-known elements of the carburetor. They are calibrated screws that regulate the flow of gasoline. There are two main ones: high – it is the large screw that fixes the tank to the carburetor – and low – it is smaller, protrudes and is next to the chimney. A third screw, cornered, corresponds to the choke and only acts when it is actuated.

* Mixture Richness Screw: better known as the air screw and is located on the outside of the carburetor.

* Idle screw: it is the largest outer screw, usually has a visible spring. By adjusting this screw we increase or decrease the engine revolutions when the throttle grip is completely closed.

After knowing the elements involved in carburetion, we are ready to tackle its cleaning or tuning.

[CONTINUACIÓN EN EL CAPÍTULO 2]. SEE HERE.